Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

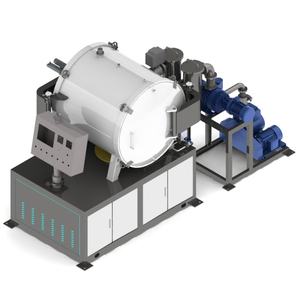

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel)

Specification of Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel

This commercial furnace takes care of high warm well. It reaches temperatures over 1300 ° C. It functions excellent for dealing with metals and steel. The furnace chamber stays sealed tight. It uses a solid air pump. This pump takes out nearly all air. It creates a near-perfect vacuum inside. This vacuum cleaner quits oxidation totally. Parts come out intense and clean. No range kinds on the surface area. The furnace uses various cooling selections. You can make use of gas quenching for rate. High-pressure nitrogen or argon cools components quickly. Oil quenching is also available. It uses an unique intense oil. This oil keeps parts shiny after cooling. The oil container sits inside the heater. This configuration maintains points cool and risk-free. The heater heats up components equally. Powerful heating elements surround the tons. Temperature level control is really precise. Digital controllers handle the warmth specifically. You can set complicated treatment cycles. The heater works for several applications. It is good for solidifying tool steel. It works for annealing stainless steel too. It handles brazing and sintering work. The framework is solid and resilient. Heavy steel composes the outer shell. High-quality insulation lines the within. This insulation saves energy. Cooling water coats secure vital components. They maintain seals and pumps from overheating. The furnace requires energies to run. It calls for electrical power. It requires cooling water supply. It links to pressed gas lines. Nitrogen or argon gas is needed. Safety and security attributes are integrated. They keep track of temperature level and pressure. They watch for water circulation issues. They trigger alarm systems for any concerns. Automatic closures prevent damages. Operators can see everything plainly. Watching ports allow visual checks. You can watch the procedure occur. The furnace layout is user-friendly. Maintenance gain access to factors are easy to reach. Loading and discharging the furnace is easy.

(Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel)

Applications of Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel

These heating systems heat metals to heats in a vacuum cleaner. This protects against oxidation. The metal surface area remains bright and clean. You see no range or discoloration. This is crucial for precision components. After heating, the metal cools rapidly. Relieving takes place in oil. Oil quenching provides fast cooling rates. This produces hard, solid components. Gas air conditioning options exist also. Nitrogen or argon gas cools the parts. Gas cooling works for some alloys. It causes much less distortion occasionally. These heating systems are crucial for setting. They set tool steels successfully. High-speed steel tools require this treatment. Passes away and molds gain sturdiness. Aerospace components require precise heat therapy. These heating systems supply consistent results. Medical implants take advantage of tidy processing. The vacuum cleaner environment keeps components sterile. Automotive components obtain dealt with for toughness. Transmission equipments utilize this modern technology. The procedure ensures dimensional security. Parts warp much less than with various other methods. Surface quality stays outstanding. No extra finishing is required. This conserves money and time. The furnaces run efficiently. They use much less oil than open systems. This lowers environmental effect. Operators work in a more secure atmosphere. Fumes and smoke are consisted of within. Vacuum problems stop fires. Overall performance is very dependable. Consistent sets are generated daily. Commercial manufacturers depend on these systems. They provide top-notch heat therapy. Steel components accomplish peak buildings.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel

Here are 5 FAQs for the Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel:

1. What makes this vacuum furnace good for bright hardening steel?

This furnace heats metal parts very evenly in a vacuum. The vacuum stops air from reacting with the steel surface. This keeps the surface clean and bright. After heating, parts cool quickly in oil or gas. This fast cooling hardens the steel effectively. The clean surface stays bright.

2. Why use a vacuum for quenching?

Heating steel in air causes oxidation. Oxidation makes a dark scale on the surface. This scale must be removed later. It wastes time and material. The vacuum furnace removes air. No air means no oxidation. Parts come out with a clean, bright finish. This saves work after hardening.

3. What cooling options does this furnace offer?

The furnace offers two main cooling methods. You can use high-pressure gas quenching. Nitrogen or argon gas cools the parts fast. You can also use oil quenching. Parts move quickly from the hot zone into an oil bath. The oil cools them very rapidly. Both methods achieve high hardness.

4. How hot can this furnace get?

This furnace reaches very high temperatures. It handles temperatures up to 1320°C or higher. This high heat is needed for many steel types. Steels must reach their specific hardening temperature. This furnace provides the necessary heat range. It ensures proper hardening.

5. What materials can it process?

The furnace processes many metals needing bright hardening. It works well with tool steels, die steels, high-speed steels. It also works well with stainless steels and other alloys. The vacuum protects the material. The controlled heating and cooling give consistent results. It suits parts needing high hardness and a bright finish.

(Industrial High Temperature Bright Oil Quenching Gas Cooling Vacuum Furnace For Metals Steel)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Horizontal Vacuum Annealing Furnace Competitive Treatment Furnace For Bright Annealing Of Nonferrous Metals

China Vacuum Sintering Debinding Furnace MIM Furnace

1100C Vacuum Chamber Furnace muffle furnace with Feedthrough flange

Kiln Good Performance 1200C Hydrogen Vacuum Tube Atmosphere Furnace Factory

ZSJ Series Single-chamber Graphite Furnace High Temperature Vacuum Sintering Furnace