Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

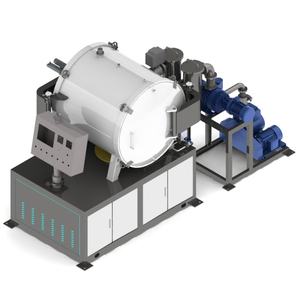

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Low Temperature Vacuum Brazing Furnace For Aluminium Product Factory )

Specification of Low Temperature Vacuum Brazing Furnace For Aluminium Product Factory

This furnace brazes aluminum parts perfectly. Aluminum factories need reliable brazing. This vacuum furnace does the job well. It uses low temperatures. This protects sensitive aluminum alloys. The vacuum environment is crucial. It stops oxidation completely. Oxidation ruins aluminum joints. Clean, strong bonds are essential. The furnace heats uniformly. Temperature control is very precise. This ensures consistent results every time. Parts won’t warp or distort. Quality stays high. Production waste drops significantly. The heating system works efficiently. It saves energy. Operating costs go down. Cooling happens quickly after brazing. Fast cooling boosts throughput. You get more parts done daily. The chamber size is generous. It handles large assemblies or many small parts. Loading and unloading are straightforward. The design prioritizes user safety. Operators work confidently. Automation options exist. You can integrate it into production lines easily. This furnace needs little upkeep. Maintenance is simple and cheap. Downtime is minimized. Your factory keeps running smoothly. The furnace is built tough. It lasts for years. Performance stays reliable. You get a good return on investment. The technical support team is strong. They help with setup and questions. Custom solutions are available. Specific needs get addressed. Ask about your application.

(Low Temperature Vacuum Brazing Furnace For Aluminium Product Factory )

Applications of Low Temperature Vacuum Brazing Furnace For Aluminium Product Factory

Low temperature vacuum brazing furnaces are essential tools for aluminum product factories. They join aluminum parts using heat without melting the base metal. This happens inside a special sealed chamber. The vacuum environment removes air. This prevents oxidation during the heating process. Oxidation makes weak joints. The vacuum stops that. The furnace controls temperature very precisely. This is key. Aluminum melts at a lower temperature than many other metals. The furnace runs hot enough to melt the filler metal. It keeps the aluminum parts solid. This creates strong, leak-proof bonds.

Factories use these furnaces for many aluminum assemblies. Heat exchangers are a big one. Think radiators or intercoolers. These need complex internal pathways. They must not leak. Vacuum brazing builds these perfectly. It makes reliable joints inside the tiny tubes and fins. Electronics cooling systems often use aluminum too. Vacuum brazing attaches heat sinks and cold plates securely. Aerospace factories rely on this method. It makes strong, lightweight parts for planes. Automotive factories need it for aluminum components. These include air conditioning parts and transmission coolers. Even complex shapes are possible. The furnace heats the whole assembly evenly. This avoids warping or weak spots. The vacuum ensures clean joints every time.

This process offers big advantages. The joints are very strong. They resist corrosion well. The finished parts look clean. There’s no flux residue to clean off. The process is repeatable and reliable. Factories get consistent quality. It saves time compared to some older methods. Less rework is needed. It can join different aluminum alloys together. It also bonds aluminum to some other metals like steel. This opens more design options. Using a vacuum furnace lowers energy costs. It runs cooler than furnaces for steel brazing. The lower temperature saves power. It extends the furnace’s life too. Less heat means less wear on the equipment. Factories get better products faster.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Low Temperature Vacuum Brazing Furnace For Aluminium Product Factory

What temperature does low temperature vacuum brazing for aluminum use?

It uses temperatures between 580°C and 620°C. This range melts the brazing filler metal. The base aluminum does not melt. It joins parts securely.

Why use a vacuum for brazing aluminum?

A vacuum removes air. Air contains oxygen. Oxygen causes oxidation on aluminum surfaces. Oxidation stops proper brazing. A vacuum prevents oxidation. Clean joints form. The joints are strong and leak-tight.

What materials work with low temperature vacuum brazing?

This process works well for aluminum alloys. It works for parts with complex shapes. It works for assemblies needing high strength. Common examples are heat exchangers. Automotive condensers use it. Radiators use it. Other aluminum parts needing strong bonds use it.

How important is cooling after brazing?

Controlled cooling is essential. Cooling happens inside the furnace. Fast cooling causes thermal stress. Thermal stress can crack parts. Slow cooling prevents cracking. It ensures stable part dimensions. Proper cooling makes reliable products.

How do you prevent leaks in brazed aluminum parts?

Preventing leaks starts with preparation. Surfaces must be extremely clean. Proper filler metal placement is critical. The vacuum level must be correct. Temperature uniformity throughout the furnace matters. Following these steps minimizes leaks. It produces high-quality assemblies.

(Low Temperature Vacuum Brazing Furnace For Aluminium Product Factory )

REQUEST A QUOTE

RELATED PRODUCTS

1200C 1400C 1600C 1700C 1800C 2200C High Vacuum Atmosphere Sintering Furnace With Atmosphere Control

Jewelry Tools Equipment 2L Lost Wax Cast Casting Metal Melting Gold Melting Furnace Jewellery Vacuum Casting Machine

Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace

1800C Vacuum belt furnace Vacuum melting furnace Electric arc furnace

1200 Degree Top-Open High Temperature Vacuum Tube Furnace with Quartz Tube for Lab