Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

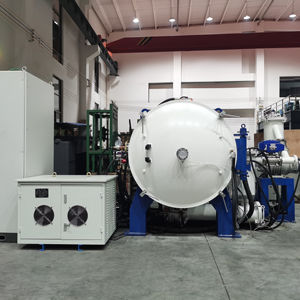

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Vacuum Brazing Furnace Oven Silver/Copper/Nickel-based Vacuum Brazing furnace)

Specification of Vacuum Brazing Furnace Oven Silver/Copper/Nickel-based Vacuum Brazing furnace

This vacuum brazing furnace oven joins metal parts permanently. It uses heat inside a sealed chamber with no air. This method prevents oxidation. Oxidation ruins the joint quality. The furnace works great for silver, copper, and nickel-based brazing alloys. These alloys need precise heat and clean conditions.

The furnace reaches very high temperatures. It must melt the brazing material. The heat stays uniform across the entire work area. This ensures every joint heats evenly. The vacuum system removes all air from the chamber. It creates a very low pressure environment. This deep vacuum stops any surface contamination. Clean surfaces are vital for a strong bond.

The chamber inside is spacious. It holds large parts or many smaller items at once. Different sizes are available. The cooling system works fast after heating. Quick cooling saves time. It also helps achieve the right material properties. The furnace uses advanced controls. Operators set exact temperature profiles. They also set precise vacuum levels. The controls are easy to use. They guarantee repeatable results every run.

Safety is built into the design. The furnace monitors conditions constantly. It alerts operators to any issues. This protects both the equipment and the valuable parts inside. Reliable performance is key for industrial use. This furnace delivers consistent, high-quality brazed joints. It meets the demands of tough applications.

(Vacuum Brazing Furnace Oven Silver/Copper/Nickel-based Vacuum Brazing furnace)

Applications of Vacuum Brazing Furnace Oven Silver/Copper/Nickel-based Vacuum Brazing furnace

Vacuum brazing furnaces are special ovens. They join metal parts together very strongly. This happens inside a vacuum, meaning no air is present. The heat melts a special filler metal, not the main parts. Silver, copper, and nickel alloys are common filler materials. This process creates clean, reliable bonds without oxidation.

These furnaces are vital in aerospace manufacturing. They build jet engine components like turbine blades and fuel nozzles. The vacuum prevents contamination. It ensures the parts can handle extreme heat and stress safely. Strong joints are critical for flight safety.

The automotive industry uses these ovens too. They make complex parts like aluminum heat exchangers for air conditioning. Vacuum brazing creates leak-proof seals. This is essential for system performance and longevity. Turbochargers and transmission parts also benefit from this clean joining method.

Medical device makers rely on vacuum brazing. It assembles surgical instruments and implants. The process keeps surfaces perfectly clean. It avoids any residues that could harm patients. Biocompatibility is non-negotiable in medical applications.

Electronics manufacturing needs precise joining. Vacuum furnaces braze parts in power modules and semiconductor equipment. They prevent electrical short circuits caused by oxidation. The bonds must conduct electricity well and last a long time.

Energy sector equipment requires durable joints. Vacuum brazing helps make heat exchangers for power plants. It also builds parts for solar thermal energy systems. These parts face high temperatures and pressures daily. Reliable brazing prevents failures.

Metal fabricators use these furnaces for custom projects. They join dissimilar metals effectively. This includes combining steel with copper or aluminum. The vacuum environment makes this possible without weak spots. It allows designers more freedom in material choices.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Vacuum Brazing Furnace Oven Silver/Copper/Nickel-based Vacuum Brazing furnace

What is vacuum brazing? Vacuum brazing joins metal parts using a filler metal. The process happens inside a sealed furnace. The furnace chamber has all the air removed. This creates a vacuum environment. Heat is applied to melt the filler metal. The molten metal flows into the joint between the parts. It then cools and solidifies. This forms a strong, clean bond. Vacuum brazing is precise. It is used for critical components.

Why use a vacuum? A vacuum environment is crucial. It prevents oxidation during heating. Oxidation can ruin the joint. The vacuum also helps remove surface contaminants. Clean surfaces are essential for good wetting. Good wetting means the filler metal spreads properly. The vacuum protects the parts. It ensures a high-quality, reliable braze joint. Clean joints are stronger. They last longer.

What metals can be brazed? Vacuum brazing furnaces handle various alloys. They work well with silver-based filler metals. Copper-based fillers are also common. Nickel-based fillers are used for high-temperature applications. The furnace can braze stainless steel, titanium, and superalloys. It suits many different base metals. The vacuum atmosphere protects sensitive materials. It allows for brazing complex assemblies.

How is temperature controlled? Precise temperature control is vital. Modern furnaces use advanced controllers. Thermocouples measure the temperature inside. The controller adjusts the heating elements. This keeps the temperature very steady. Uniform heating is important. It ensures the filler metal melts evenly. It prevents damage to the parts. Accurate profiles are followed. This guarantees consistent results every time.

What are the benefits? Vacuum brazing offers distinct advantages. It produces joints with excellent strength. The joints are clean and free from flux residue. Flux is often unnecessary in a vacuum. This eliminates post-braze cleaning steps. The process allows for complex part geometries. It provides repeatable, high-quality results. Vacuum brazing is reliable for demanding applications.

(Vacuum Brazing Furnace Oven Silver/Copper/Nickel-based Vacuum Brazing furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Well vacuum industrial annealing furnace

Vacuum calciner high temperature pyrolysis furnace for clean spinneret

2L Lost Wax Cast Jewelry Tools Casting Equipment Gold Smelt Vacuo Metal Melting Furnace Jewellery Vacuum Casting Machine

200kg High Temperature Heat Treatment Vacuum Induction Melting Furnace

Nitrogen atmosphere controlled vacuum chamber furnace dust free production