Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

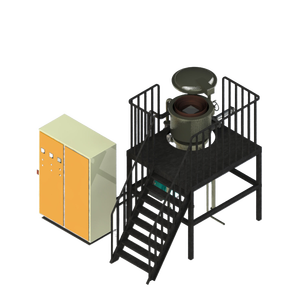

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Vacuum Annealing Furnace For Heating Equipment Resistance Furnace)

Specification of Vacuum Annealing Furnace For Heating Equipment Resistance Furnace

This vacuum annealing furnace heats steels in a vacuum. It stops air from responding with warm metal. This keeps the steel surface area tidy. Oxidation and scaling are avoided. The furnace deals with numerous steels needing annealing.

The heater reaches high temperatures. It heats up to 1300 levels Celsius or more. This matches several metals. Various materials need various heat degrees. The heater gives this variety. Consistent home heating is essential. Warm spreads equally inside the chamber. This ensures constant treatment results.

A strong vacuum cleaner system is essential. It gets rid of air from the home heating chamber. The system accomplishes a reduced pressure. Excellent vacuum degrees are possible. Pressure might reach 10 ^ -5 torr or lower. This deep vacuum cleaner produces a clean setting. Contamination threats are reduced.

Heating uses resistance aspects. These components border the workspace. They transfer warmth properly. Temperature control is exact. Advanced systems take care of the heat precisely. Setpoints are preserved reliably. Temperature level uniformity is kept track of.

Cooling down takes place inside the vacuum. The chamber cools down gradually. Controlled cooling rates are important. Details cooling rates are needed for different steels. The heater permits this control. Air conditioning can be done under vacuum or inert gas.

The heating system has a sturdy chamber. It endures vacuum stress and heat. Insulation keeps warm inside efficiently. Energy use is optimized. The layout focuses on security and dependability. Operation is uncomplicated.

A control board handles the furnace. Operators set the home heating program. They set the temperature curve. They set the vacuum level. They set the cooling price. The system automates the procedure. Hand-operated override is feasible. Information logging tracks the cycle.

This furnace is for annealing. It hardens stainless steel. It hardens tool steel. It anneals nickel alloys. It anneals titanium parts. It anneals various other special steels. The vacuum cleaner makes sure intense surface areas. It prevents decarburization. Components come out clean and ready. Consistent material residential properties are attained.

(Vacuum Annealing Furnace For Heating Equipment Resistance Furnace)

Applications of Vacuum Annealing Furnace For Heating Equipment Resistance Furnace

Vacuum annealing furnaces are special home heating ovens. They warm products inside a sealed chamber. This chamber has almost all the air drew out. This develops a vacuum cleaner. The vacuum cleaner setting is essential. Resistance heating systems create the heat required. Electric currents flow with heating elements. These elements fume. They move heat to the job inside the chamber. This procedure is called annealing.

Annealing softens metals. It eases inner anxieties. It transforms the material’s framework. This boosts its homes. Doing this in a vacuum cleaner is important. It stops oxygen from reacting with the steel. Oxidation creates surface damages. It develops undesirable scale. Vacuum cleaner annealing stops this. The steel remains clean and bright. There is no need for extra cleaning after home heating. This conserves effort and time.

These heaters likewise quit contamination. No air implies no pollutants can adhere to the material. This is important for sensitive applications. Electronics need really pure metals. Medical implants call for flawless surface areas. Aerospace parts demand high reliability. Vacuum annealing guarantees this pureness. It permits specific control over the environment. Operators can add certain gases if required. Hydrogen or argon prevail selections. This gives a lot more versatility.

Lots of markets rely upon vacuum cleaner annealing heating systems. Metalworking stores utilize them for tool steel. Suppliers harden critical aerospace elements. Electronic devices manufacturers deal with copper wires and contacts. Jewelers warm rare-earth elements without staining. Study laboratories research study material behavior under regulated problems. The ability to warmth without oxidation is critical. It enables high-quality outcomes. It supports innovative manufacturing procedures. Resistance heating provides steady, reliable temperatures.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Vacuum Annealing Furnace For Heating Equipment Resistance Furnace

What is a vacuum annealing furnace?

It is a special furnace for heating metal parts in a vacuum environment. The vacuum means very low air pressure inside the furnace. This furnace heats materials to high temperatures, holds them there for a while, then cools them slowly. This process is called annealing.

Why use a vacuum for annealing?

Air contains oxygen. Oxygen can cause problems at high heat. It can make metal surfaces oxidize or scale. A vacuum removes the air. This prevents oxidation. It keeps the metal surface clean and bright. It also avoids contamination. This is critical for sensitive materials like titanium or special alloys.

What temperatures can it reach?

These furnaces get very hot. They typically heat between 800 degrees Celsius and 1320 degrees Celsius. Some specialized models go even hotter. The exact temperature needed depends on the material being annealed. Different metals require different heat levels for best results.

What materials are annealed in vacuum?

Many materials benefit from vacuum annealing. Common examples include stainless steel, tool steel, nickel alloys, titanium alloys, and copper alloys. Electronics parts like silicon wafers also use this process. Any material needing a clean, oxide-free surface after heat treatment is a good candidate.

What advantages does it offer?

Vacuum annealing gives superior results. It produces bright, clean surfaces without oxidation. This means less work later. No need for extra cleaning or pickling. It provides precise control over the heating and cooling process. This ensures consistent material properties. It also allows annealing reactive metals safely.

(Vacuum Annealing Furnace For Heating Equipment Resistance Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

LIYI 1700 Degree Heat Treatment Electric Vacuum Argon Atmosphere Sintering Furnace

PLC Control HMI Electric Resistance Pit Type Vacuum Industrial Nitriding Nitrocarburizing Furnaces Equipment

200kg High Temperature Heat Treatment Vacuum Induction Melting Furnace

High Temperature 1200C – 1800C Vacuum Tube Furnace with Multiple Tube Sizes

Thermos Cookware Production Line Stainless Steel Metal Aluminum Vacuum Flask Water Bottle Making Machine