Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

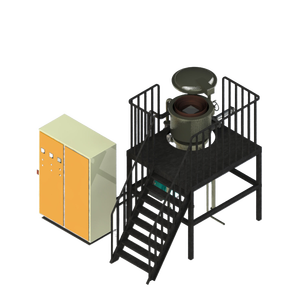

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Professional Customized 1600C Vacuum Sintering Furnace for High Temperature Metal Processing)

Specification of Professional Customized 1600C Vacuum Sintering Furnace for High Temperature Metal Processing

This vacuum sintering heating system reaches 1600 degrees Celsius. It handles high temperature metal handling well. The chamber is made from solid materials. It holds up against extreme warm and vacuum cleaner conditions. The vacuum system is powerful. It removes air and gases effectively. This avoids oxidation throughout sintering. The burner are advanced. They heat the chamber uniformly. Temperature level control is precise throughout the process. Cooling occurs successfully after sintering. The furnace cools off safely. This protects the finished components. The control system is straightforward. Operators collection and screen parameters easily. Security functions are included. They secure both the devices and the drivers. The furnace design permits modification. Various dimensions and arrangements are possible. Certain home heating prices or cooling down speeds can be set. The heater suits various industries. Aerospace, medical, and tooling applications benefit. It processes materials like tungsten or titanium alloys successfully. Consistent results are attained batch after set. The inner structure sustains different configurations. Fixtures and trays hold parts firmly. Temperature level harmony is key for top quality. The whole chamber heats uniformly. Hot spots are decreased. Vacuum cleaner degrees are essential. Reduced stress is maintained reliably. Contamination dangers are reduced. The cooling system uses water or gas. Rapid cooling choices are offered. This heater satisfies demanding manufacturing requirements.

(Professional Customized 1600C Vacuum Sintering Furnace for High Temperature Metal Processing)

Applications of Professional Customized 1600C Vacuum Sintering Furnace for High Temperature Metal Processing

This 1600C vacuum sintering furnace is built for demanding high-temperature metal jobs. It creates a strong vacuum inside. This vacuum is key. It removes air and gases. This stops oxidation and contamination during heating. You get very pure, clean finished parts. The furnace heats up to 1600 degrees Celsius. This is hot enough for many tough materials. The temperature control is precise. It keeps the heat steady and even across your parts. This uniform heating is vital. It ensures consistent quality batch after batch. It’s perfect for sintering MIM parts. MIM parts need this controlled vacuum heat to become dense and strong. It’s also great for sintering Powder Metallurgy (PM) components. PM parts require high heat in a vacuum to bond properly. Brazing benefits hugely from this furnace too. The vacuum environment lets filler metals flow cleanly. You get strong, reliable joints without flux residue. Annealing tough metals like titanium or tungsten alloys is another key job. The vacuum prevents surface damage. It allows for controlled cooling. This improves the metal’s structure and properties. This furnace serves industries needing top performance. Aerospace uses it for critical engine and airframe parts. Medical device makers rely on it for precise, biocompatible implants. The automotive sector uses it for high-strength transmission and turbocharger components. It handles exotic alloys well. Materials like tungsten, molybdenum, Inconel, and titanium work well here. They need the high heat and clean atmosphere. If you process metals needing extreme temperatures in a pure environment, this furnace is a solid choice. It delivers reliable results for sintering, brazing, and annealing.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Professional Customized 1600C Vacuum Sintering Furnace for High Temperature Metal Processing

What temperature does this furnace reach?

This furnace heats up to 1600°C. That’s hot enough for sintering advanced metals like tungsten or molybdenum. High temperatures ensure strong, dense parts. We build it to hold that heat reliably.

How good is the vacuum?

The vacuum is very strong. We achieve low pressure levels. This stops oxidation and removes impurities during heating. Clean parts result from this. It helps achieve better material properties.

How fast does it cool down?

Cooling speed is adjustable. Faster cooling means quicker production cycles. Slower cooling might be needed for some delicate materials. We design the system for efficient temperature control. You get flexibility.

Can you change the furnace design?

Yes, customization is key. We alter the chamber size, heating zones, or cooling systems to fit your needs. Tell us your specific process requirements. We build the furnace to match them exactly.

What maintenance does it need?

Regular maintenance keeps it running well. This includes checking vacuum seals and heating elements. We provide clear guidelines. Spare parts are readily available. Proper care ensures long furnace life.

(Professional Customized 1600C Vacuum Sintering Furnace for High Temperature Metal Processing)

REQUEST A QUOTE

RELATED PRODUCTS

2200℃ ultra-high temperature vacuum sintering furnace High quality large laboratory heating equipment

Lab Vacuum Brazing Furnace vacuum aluminium brazing furnace university research and development for Stainless steel brazing

Vacuum Atmosphere Hydrogen Furnace With FP93 Temperature Control

Stainless Steel View Port vacuum Diamond Growing Lab Chamber For 6KW MPVCD Microwave Spherical Tube Chemical vacuum Cavity

PLC Controlled Four-Layer Furnace Oven Horizontal Glass Laminating Machine Vacuum Smart Glass Making Machine Glass Processing