Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

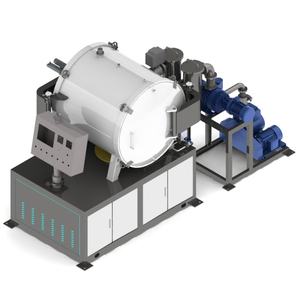

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(High Temperature Lab Furnace With PID Controller For Vacuum Or Atmosphere Sintering)

Specification of High Temperature Lab Furnace With PID Controller For Vacuum Or Atmosphere Sintering

This high temperature laboratory heating system handles requiring sintering tasks. It works perfectly for both vacuum and atmospheric conditions. Specific temperature level control matters here. That’s why it includes a clever PID controller. This controller regularly views the heating system temperature. It makes little changes immediately. This maintains the temperature exceptionally secure. Steady temperature levels are essential for good sintering results. You prevent problems like bending or weak parts.

The furnace reaches extremely high temperatures. It conveniently strikes 1700 ° C or higher. Such extreme warmth is needed for sintering numerous advanced products. The heating system chamber is built challenging. It makes use of top-grade refractory materials inside. These products resist severe warm incredibly well. They additionally last a very long time. The heating elements are very carefully put. This setup makes certain also heat spreads throughout the chamber. Regular heating is vital for uniform sintering.

You can use this heating system with or without air. It secures securely for vacuum cleaner operation. A solid vacuum pump gets rid of the air. This is essential for sintering oxygen-sensitive materials. Sometimes you require particular gases instead. The furnace additionally sustains controlled environment work. You can pump in inert gases like argon or nitrogen. This safeguards products during high-heat handling.

Safety is constantly crucial. This heating system has built-in safeguards. It keeps an eye on for overheating automatically. It cuts power if things get also hot. This safeguards both the heating system and your examples. The outer covering stays great enough to touch. Operators remain secure from burns. The controls are straightforward. You set the preferred temperature easily. You pick the heating price. You program for how long the hold time lasts. The PID controller deals with the rest. It provides precise temperature level profiles constantly. This reliability is essential for repeatable lab job.

(High Temperature Lab Furnace With PID Controller For Vacuum Or Atmosphere Sintering)

Applications of High Temperature Lab Furnace With PID Controller For Vacuum Or Atmosphere Sintering

High temperature lab furnaces with PID controllers are important for sintering. They specifically warmth products to extremely heats. These furnaces function under vacuum cleaner or regulated atmospheres. This control is crucial for many sintering applications. Accurate temperature management is vital. The PID controller makes this possible. It regularly changes the home heating result. This guarantees the precise temperature setpoint is preserved. Secure temperature levels are vital for regular sintering outcomes. Without great control, products may sinter inadequately.

Vacuum sintering needs removing air from the chamber. This protects against oxidation of delicate materials. Vacuum cleaner is essential for sintering certain ceramics and metals. It likewise assists eliminate binders throughout the process. Environment sintering makes use of details gases inside the chamber. Common gases include nitrogen, argon, or hydrogen. These gases secure reactive products from oxidation. They additionally prevent unwanted chemical reactions. Environment control enables sintering materials needing details settings.

These heaters sinter a large range of materials. They process ceramics, steels, and composite powders. Common applications include producing technological porcelains. Examples are alumina, zirconia, and silicon carbide. Metal powder sintering is another vital usage. It generates strong metal components from powders. Carbide tool sintering also relies upon these heaters. The heaters attain temperatures over 1700 ° C. Some designs get to 1800 ° C or greater. This high heat is necessary for densifying products. Specific temperature ramping is an additional function. Controlled heating and cooling rates are important. They prevent thermal shock to the parts. This guarantees sintered elements have excellent residential or commercial properties.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Lab Furnace With PID Controller For Vacuum Or Atmosphere Sintering

What does a high temperature lab furnace with PID controller do?

This furnace heats materials to very high temperatures. It controls the temperature precisely using a PID controller. This is vital for sintering processes. Sintering bonds powder particles together without melting them completely. The furnace works under vacuum or specific gas atmospheres. This prevents unwanted reactions during heating.

How does the PID controller improve furnace operation?

The PID controller constantly checks the furnace temperature. It compares the actual temperature against the set point. It then adjusts the heating power automatically. This adjustment is proportional to how far off the temperature is. It also considers how quickly the temperature is changing. This results in fast, accurate temperature control. It minimizes overshooting or undershooting the target temperature.

What temperatures can this furnace reach?

These lab furnaces achieve high temperatures. Common maximum temperatures are 1700°C, 1800°C, or even higher. The exact maximum depends on the furnace design and heating elements. Furnaces using silicon carbide elements typically reach up to 1600°C. Molybdenum disilicide elements allow temperatures up to 1800°C. Some special designs reach 2000°C or more.

Can I use different atmospheres inside the furnace?

Yes, you can. The furnace chamber can be sealed. Air inside can be pumped out to create a vacuum. Specific gases can be pumped in instead. Common gases include nitrogen, argon, hydrogen, or forming gas mixes. The atmosphere type depends on your material. It prevents oxidation or promotes specific reactions during sintering.

What maintenance does the furnace need?

Regular maintenance keeps the furnace working well. Check the heating elements for damage or wear. Clean the furnace chamber after use to remove debris. Inspect door seals for leaks. Ensure thermocouples measuring temperature are accurate. Follow the manufacturer’s instructions for specific care steps. Proper maintenance ensures long furnace life and reliable results.

(High Temperature Lab Furnace With PID Controller For Vacuum Or Atmosphere Sintering)

REQUEST A QUOTE

RELATED PRODUCTS

High quality customizable vacuum coating, hot evaporation, pure molybdenum evaporation boat, molybdenum boat

Custom High Pure Graphite Parts for Vacuum Furnace Industrial Furnaces

Superior Corrosion-Resistant Vacuum Furnace Heating Chamber

Heat Treatment Single-chamber High Pressure Vacuum Gas Quenching Furnace

Factory Custom Isostatic Graphite Heating Element Graphite Heat Parts for Vacuum Furnace