Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

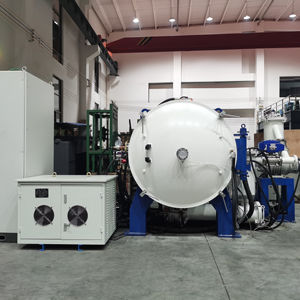

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Heat Exchangers And Cold Plates (heating, Cooling) Brazing vacuum furnace Electric furnace Made In China)

Specification of Heat Exchangers And Cold Plates (heating, Cooling) Brazing vacuum furnace Electric furnace Made In China

Heat exchangers and cold plates are important parts in many industries. They manage heat transfer effectively. You find them in electronics cooling, electric vehicles, and industrial machinery. They move heat away from hot components. They also provide precise heating or cooling where needed. China makes these products using advanced methods. Brazing is a key process in their production. Brazing joins metal parts strongly and permanently.

Two main types of furnaces are used for brazing. Vacuum furnaces offer a controlled environment. This environment prevents oxidation during the high-heat brazing process. Oxidation weakens joints. Vacuum brazing creates very clean, strong, leak-free joints. These joints are vital for reliability. Vacuum furnaces are excellent for complex assemblies. They work well with sensitive materials like aluminum and stainless steel. They ensure high-quality bonds essential for critical applications.

Electric furnaces are another common choice. They provide precise temperature control. This control is crucial for consistent brazing results. Manufacturers use them for larger batches. They offer efficient production cycles. Electric furnaces handle various brazing alloys effectively. They support the production of durable heat exchangers and cold plates. Both furnace types ensure good thermal conductivity across the joint.

Chinese factories use these furnaces extensively. They produce high volumes of heat exchangers and cold plates. The focus is on precision and efficiency. Materials commonly used include aluminum, copper, and stainless steel. These materials offer good thermal properties. Manufacturers select materials based on the application requirements. Strict quality control is maintained throughout production. This ensures every unit meets performance standards. Testing confirms heat transfer efficiency and structural integrity. The goal is reliable performance in demanding environments. Vacuum and electric brazing furnaces make this possible.

(Heat Exchangers And Cold Plates (heating, Cooling) Brazing vacuum furnace Electric furnace Made In China)

Applications of Heat Exchangers And Cold Plates (heating, Cooling) Brazing vacuum furnace Electric furnace Made In China

Heat exchangers and cold plates need strong joints to handle heating and cooling jobs well. Brazing makes these connections reliable. Special furnaces do the brazing. Vacuum brazing furnaces and electric brazing furnaces from China are good choices.

Vacuum brazing furnaces are important for tricky jobs. They remove all air from the chamber before heating. This prevents oxidation. Oxidation ruins joints. Clean parts inside a vacuum mean perfect, leak-free bonds. Aluminum, stainless steel, titanium – they all braze beautifully in vacuum furnaces. These furnaces give precise temperature control. That control is vital for top quality.

Electric brazing furnaces are another solid option. They use electric heat. They are often more affordable than vacuum furnaces. They still deliver accurate brazing for many heat exchanger and cold plate projects. Users get consistent results without big spending. Electric furnaces handle production needs well.

China makes excellent vacuum and electric brazing furnaces. Modern factories use good materials and smart designs. Skilled workers build them carefully. These furnaces meet tough standards. They braze parts fast and right. This saves time and money. Many companies worldwide choose Chinese furnaces. They trust the performance and value.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Heat Exchangers And Cold Plates (heating, Cooling) Brazing vacuum furnace Electric furnace Made In China

Why use vacuum brazing for heat exchangers? Vacuum brazing creates very strong joints. It seals parts perfectly. This stops leaks. Brazing inside a vacuum furnace prevents oxidation. Oxidation weakens joints. Vacuum furnaces don’t need flux. Flux can leave messy residue. Clean joints are crucial for heat exchangers and cold plates. They handle heating and cooling jobs.

How does the brazing furnace work? Parts are loaded into the furnace chamber. The chamber door seals tightly. Powerful pumps pull out nearly all the air. This creates a strong vacuum. Heating elements slowly warm the parts. They reach the exact brazing temperature. The parts hold at this temperature. The filler metal melts. It flows into the joints. The furnace cools the parts slowly. Slow cooling prevents stress cracks.

What temperature can these furnaces reach? Our Chinese-made electric vacuum furnaces heat reliably. They achieve high temperatures needed for brazing. Temperatures typically range from 1100°C to 1300°C. Some models go higher. Precise temperature control is vital. It ensures the filler metal melts correctly. It bonds the base materials strongly. Overheating damages parts. Underheating causes weak joints.

Are China-made furnaces reliable? Yes. Chinese manufacturers build advanced vacuum furnaces. They use proven designs. Quality materials are common now. Strict quality control checks happen. Good factories test each furnace thoroughly. Modern Chinese furnaces compete well globally. They offer similar performance. They cost less than many Western brands. Maintenance is straightforward. Parts are available.

Why is cooling rate important? Cooling speed matters after brazing. Cooling too fast is bad. It makes the metal brittle. It can cause cracks. Cooling too slow wastes time. It might weaken the metal structure. Our furnaces control cooling precisely. They use special gas quenching or slower cooling cycles. Controlled cooling ensures strong, reliable brazed assemblies. Your heat exchangers and cold plates perform better. Ask about spare parts.

(Heat Exchangers And Cold Plates (heating, Cooling) Brazing vacuum furnace Electric furnace Made In China)

REQUEST A QUOTE

RELATED PRODUCTS

Lab Vacuum Brazing Furnace vacuum aluminium brazing furnace university research and development for Stainless steel brazing

China Vacuum Annealing Hardening Furnace Oven for Heat Treatment

High Temperature 1200C – 1800C Vacuum Tube Furnace with Multiple Tube Sizes

1600 degree box vacuum furnace customized atmosphere furnace

Lab 1200C 1400C 1600C 1800C Electric Muffle Furnace High Temperature Klin Heat Vacuum Muffle Box Oven For Sintering Experiment