Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

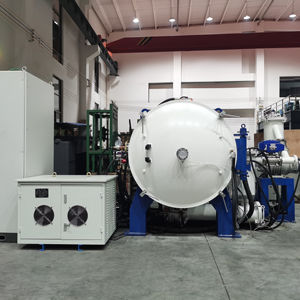

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace)

Specification of Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace

This lab induction melting furnace manages platinum-rhodium alloy blocks. It thaws and casts them under high vacuum. The vacuum is essential. It quits air from reacting with the precious metals. This keeps the alloys pure and tidy. You get high-grade binary alloy examples or tiny components.

The heating system deals with induction heating. Powerful magnets produce warm straight inside the steel. This method is fast and effective. It offers specific temperature control. You can thaw metals up to really heats, conveniently over 1800 ° C. The system remains steady throughout futures.

An unique chamber holds the alloy block. This chamber withstands the intense warmth and vacuum. You place your platinum-rhodium material inside. The furnace seals snugly. Powerful pumps pull out all the air. This creates the high vacuum setting required.

The melting process begins following. The induction coils power up. They produce solid magnetic fields. These fields make electrical currents circulation inside the steel block. The currents produce warmth instantaneously. The steel warms up quickly from within. It thaws entirely right into a liquid swimming pool.

You can after that cast the molten alloy. The furnace layout allows pouring into molds. This happens inside the vacuum cleaner. Air never ever touches the warm fluid steel. This stops oxidation and contamination. You get clean, dense spreadings with good surface areas.

Security is built in. The furnace has water air conditioning for warm components. It keeps track of temperature and vacuum levels continuously. Overheat defense cuts power if required. Emergency situation stop switches come. Operators see all important readings on a clear control board. The system is built for trusted laboratory usage.

(Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace)

Applications of Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace

This furnace thaws platinum-rhodium alloys under high vacuum cleaner. It makes use of solid induction home heating. This is essential for study and tiny manufacturing. Oxygen damages these precious alloys. This furnace eliminates oxygen entirely. The sealed chamber reaches a solid vacuum cleaner before heating starts. This safeguards the metal. It keeps the alloy pure.

The heating system obtains extremely hot. It quickly gets to over 1800 ° C. This is needed for platinum and rhodium. Induction heating functions quick. It thaws the steel rapidly inside a special crucible. You can utilize graphite or ceramic crucibles. The warmth is extremely controlled. You can hold accurate temperatures. You can additionally alter the temperature level smoothly. This control is essential completely results.

Scientists utilize this furnace in laboratories. They make tiny, pure examples of binary alloys. Jewelers use it for unique platinum-rhodium pieces. Aerospace labs require it for testing high-temperature components. The furnace can pour molten steel. It can make little bars or unique forms. Continual casting is possible. This benefits making wire or slim sheets later.

The design is robust. It deals with the intense warmth well. The vacuum system is reliable. Operation is uncomplicated. Individuals focus on the melting procedure. They do not fight the tools. Regular results take place whenever. This matters for costly materials. Researchers trust it for crucial alloy growth. Makers use it for premium small sets.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace

What makes this furnace good for platinum-rhodium alloys?

High vacuum is crucial. It stops oxygen. Oxygen ruins alloys. This furnace creates a strong vacuum. It keeps the metal pure during melting and pouring. This is vital for top-quality platinum-rhodium blocks.

Why is high vacuum needed?

Platinum and rhodium react easily with air. Air contains oxygen and nitrogen. These elements form oxides and nitrides. Contaminants weaken the alloy. Vacuum removes air. It prevents reactions. You get clean, strong alloy blocks.

How hot does it get?

The furnace reaches very high temperatures. Platinum-rhodium melts around 1800°C. This furnace exceeds that. It can heat beyond 2000°C. This ensures full melting. It allows perfect mixing of platinum and rhodium.

Is it safe for expensive metals?

Safety is a top priority. The furnace seals tightly. It stops leaks. The vacuum system is reliable. Argon gas can be used too. Argon doesn’t react. This protects your valuable platinum and rhodium from loss.

What crucible works best?

Crucible choice matters. Zirconia crucibles are common. They handle extreme heat well. They resist reaction with molten platinum-rhodium. Graphite crucibles might work sometimes. Graphite can add carbon. Carbon might contaminate the alloy. Zirconia is safer for pure alloys.

(Binary alloys high vacuum platinum rhodium alloy block smelting and casting furnace science lab induction melting furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Mini 480 Stainless Steel Thermal Vacuum Chamber Air Degassing Furnace for Coating Production Line Atomization Machine

1200C 1400C 1600C 1700C 1800C 2200C High Vacuum Atmosphere Sintering Furnace With Atmosphere Control

1700C furnace sintering inert controlled laboratory heating furnace best electric chamber vacuum atmosphere furnace

Factory Customizable Size Temp 800c 1200c 1600c 1800c 2200c Split Body Vacuum Furnace From China

New Spot Electromagnetic Vacuum Furnace for Net Burning for EPS PP PET PE ABS PMMA Plastic Cleaning