Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

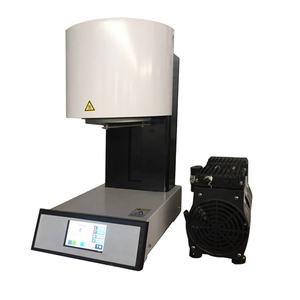

Overview of Dental Furnace

A dental furnace is a specialized piece of equipment used in dental laboratories for processes such as sintering, casting, and baking of dental prosthetics. It ensures precise temperature control and uniform heating, critical for the fabrication of high-quality crowns, bridges, and other dental restorations.

Features of Dental Furnace

Precision Temperature Control: Ensures accurate heating for optimal material properties.

Uniform Heating: Provides even heat distribution to prevent defects in dental restorations.

Programmable Settings: Allows customization of heating cycles for different materials and processes.

High-Temperature Capacity: Capable of reaching temperatures necessary for sintering ceramics and metals.

Compact Design: Space-saving design suitable for laboratory environments.

Safety Features: Includes over-temperature protection and automatic shut-off for safe operation.

(PHOENIX-10S Dental Fast Zirconia Crystallization Furnace Dental Sintering Furnace)

Specification of PHOENIX-10S Dental Fast Zirconia Crystallization Furnace Dental Sintering Furnace

The PHOENIX-10S Dental Fast Zirconia Crystallization Furnace handles zirconia sintering. This furnace transforms zirconia blocks into strong dental crowns and bridges. It offers fast crystallization cycles. This saves valuable time in the dental lab.

Precise temperature control is vital for consistent results. The PHOENIX-10S delivers this precision. It uses advanced heating elements and sensors. Temperatures reach 1600°C reliably. Uniform heat distribution prevents warping. This ensures crowns fit perfectly every time.

Speed is a major advantage. The furnace achieves fast sintering cycles. This allows labs to process more units daily. The large chamber accommodates multiple restorations simultaneously. Labs can sinter up to 10 full-contour crowns in one run. This boosts overall productivity significantly.

The user interface is straightforward. A clear touchscreen makes operation simple. Programming specific sintering profiles is easy. Staff can quickly learn how to use it. Safety features are built-in. Over-temperature protection and alarms prevent accidents. This provides peace of mind during operation.

Durability matters in a busy lab. The PHOENIX-10S is built tough. High-quality insulation minimizes heat loss. This improves efficiency and saves energy. The robust construction withstands daily use. Maintenance requirements are minimal. This furnace is a dependable workhorse for any dental laboratory.

(PHOENIX-10S Dental Fast Zirconia Crystallization Furnace Dental Sintering Furnace)

Applications of PHOENIX-10S Dental Fast Zirconia Crystallization Furnace Dental Sintering Furnace

The PHOENIX-10S Dental Fast Zirconia Crystallization Furnace is made for dental labs. It processes zirconia crowns and bridges fast. This furnace crystallizes zirconia quickly. That means faster turnaround times for dental work. Labs get their pieces ready sooner.

It heats zirconia blocks reliably. The temperature control is very precise. This is important for strong, durable restorations. Consistent heat means consistent results every time. You can trust the quality.

The furnace works well for sintering zirconia. Sintering is the heating process that hardens the material. The PHOENIX-10S does this efficiently. It produces dense zirconia structures. These structures are strong enough for teeth.

Its design is modern and easy to use. The controls are simple. Lab technicians find it straightforward. Training new staff is easy. The furnace fits smoothly into daily lab work.

The chamber size is practical. It holds multiple zirconia pieces at once. This allows for processing several items together. Batch processing saves time and energy. Labs handle more work without slowing down.

Durability is a key feature. The furnace is built strong for everyday use. It handles constant lab demands well. Reliability means less downtime. Labs keep production moving.

Energy efficiency is good. The furnace uses power wisely. This helps control operating costs. Labs save money over time. It’s a smart investment.

The PHOENIX-10S supports different zirconia materials. It works with various brands and types. Labs have flexibility in material choices. They are not limited to one supplier.

Safety features are included. The furnace operates securely. Lab staff can work without worry. Protection is built-in.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of PHOENIX-10S Dental Fast Zirconia Crystallization Furnace Dental Sintering Furnace

What is the sintering time for zirconia in the PHOENIX-10S?

The PHOENIX-10S completes a full zirconia sintering cycle in roughly 90 minutes. This fast cycle time helps dental labs get crowns and bridges to dentists much quicker. It saves significant time compared to older, slower furnaces. Labs can increase their daily output.

How precise is the temperature control?

The furnace maintains temperature within ±1°C of your set point. This tight control is critical. It ensures consistent, high-quality results every time you sinter zirconia. Uniform heating prevents weak spots or cracks in the final restoration. Good temperature control means reliable products.

Are there safety features?

Yes, safety is built-in. The furnace door locks securely during operation. This prevents accidental openings when it’s hot inside. It also has an advanced cooling system. This system brings the furnace chamber temperature down safely after sintering is done. You avoid burns or damage.

Is installation complicated?

No, installation is straightforward. The PHOENIX-10S plugs into a standard wall outlet. You don’t need special wiring or electrical work. Setting it up on a countertop is simple. You can be ready to start sintering zirconia very quickly after delivery.

What maintenance is required?

Maintenance needs are minimal. Regularly wipe down the exterior to keep it clean. Check the chamber occasionally for any debris or residue. Follow the cleaning instructions in the manual. This basic care helps ensure long-term, trouble-free performance. It keeps the furnace working well.

(PHOENIX-10S Dental Fast Zirconia Crystallization Furnace Dental Sintering Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

No compressed air needed Low dental porcelain press furnace

LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used

dental lab press furnace for lithium disilicate press ingots

Box Type Sintering Furnace Muffle Heater Small Debinding Dental Zirconia Zetin Lithium Manganate Tungsten Soft Metal

Dental sintering furnace