Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

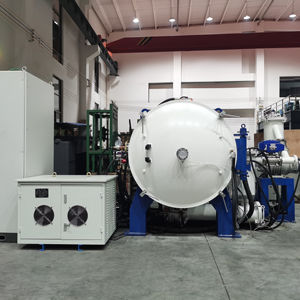

Overview of Vacuum Furnace

A vacuum furnace is a type of industrial furnace that operates in a vacuum environment to eliminate contamination and oxidation during heating processes. It is commonly used for heat treatment, sintering, brazing, and other high-precision applications where purity and control are critical.

Features of Vacuum Furnace

Contamination-Free Environment: Eliminates oxidation and impurities by operating in a vacuum.

High-Temperature Capability: Can reach extremely high temperatures while maintaining process integrity.

Precision Control: Offers accurate temperature and atmosphere control for consistent results.

Versatile Applications: Suitable for heat treatment, sintering, brazing, and more.

Energy Efficiency: Designed to optimize energy use and reduce operational costs.

Safety Mechanisms: Includes safety features like pressure relief valves and emergency shut-off systems.

(Muffle Furnace Oven 1000/1200°C Heat Treatment Vacuum Atmosphere Box Ceramic Fiber Laboratory Heating Equipment)

Specification of Muffle Furnace Oven 1000/1200°C Heat Treatment Vacuum Atmosphere Box Ceramic Fiber Laboratory Heating Equipment

This Muffle Heater Stove deals with severe warm. It reaches temperature levels approximately 1000 ° C or 1200 ° C. You need this power for hard lab job. Heat treatment tasks need specific control. This heater supplies that. It heats up materials consistently inside its chamber. The box-type chamber is built solid. You obtain trustworthy results each time.

A vacuum cleaner alternative is offered. Pump out the air inside the chamber. Warm sensitive products securely. Air can often ruin your sample. Vacuum cleaner heating stops that. Environment control is one more feature. Introduce special gases right into the chamber. Produce the precise environment your material needs. Nitrogen or argon are common choices. This versatility is crucial for innovative processes.

Ceramic fiber insulation makes this furnace efficient. It warms up swiftly. It holds the warm well inside. This conserves you energy. It cools off faster as well. You save time between experiments. The external covering stays much cooler. This safeguards your lab room. It keeps individuals safer.

Safety and security is built-in. Over-temperature defense is common. It quits the heating system obtaining too hot. This safeguards your samples. It safeguards the furnace itself. Car shut-off attributes include additional safety. The style includes cool-touch surface areas. Handle the furnace securely after operation. Digital regulates make operation simple. Set the temperature you desire. Establish the time required. The furnace does the rest. Monitor the process conveniently.

(Muffle Furnace Oven 1000/1200°C Heat Treatment Vacuum Atmosphere Box Ceramic Fiber Laboratory Heating Equipment)

Applications of Muffle Furnace Oven 1000/1200°C Heat Treatment Vacuum Atmosphere Box Ceramic Fiber Laboratory Heating Equipment

This muffle furnace stove takes care of high-temperature tasks dependably. It warms products as much as 1000 or 1200 degrees Celsius. You need that sort of heat for serious laboratory job and commercial processes. The vacuum cleaner ambience box is a crucial feature. It lets you procedure examples inside a secured chamber. You eliminate the air. You can likewise pump in unique gases like nitrogen or argon. This controlled setting is important. It quits products from oxidizing or reacting terribly during heating. You get consistent results.

The ceramic fiber insulation matters a whole lot. It lines the chamber wall surfaces. This insulation heats up quick. It cools down rapidly as well. It saves energy contrasted to older brick-lined heating systems. You invest less on power. The style maintains the outdoors cool. Operators stay secure. The digital controller is simple. You set the temperature quickly. You program heating & cooling steps. You set timers. You see whatever on the screen. It holds the temperature stable. This precision is crucial for experiments.

Individuals utilize this heater in numerous ways. Laboratories depend on it. They heat-treat steels for solidity screening. They harden glass examples. They sinter porcelains. Colleges utilize it for materials science study. Jewelers require it for casting rare-earth elements without oxidation. Factory utilize it for tiny batch production. They perform brazing procedures. They examine new alloys. The vacuum or gas atmosphere shields sensitive components. Excavators even use it for analyzing artifacts. It offers adaptability. It manages various materials well. Its small size fits well on laboratory benches. It delivers powerful home heating for its impact. You obtain professional performance without big area needs.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Muffle Furnace Oven 1000/1200°C Heat Treatment Vacuum Atmosphere Box Ceramic Fiber Laboratory Heating Equipment

What is this furnace oven?

This is a muffle furnace oven. It heats materials inside a special sealed box. This box is called a muffle. The furnace reaches very high temperatures. It can go up to 1000°C or 1200°C. People use it in labs and workshops. It treats materials with heat. This process is called heat treatment.

Why use vacuum inside?

The furnace can create a vacuum inside the heating chamber. Removing air prevents reactions with oxygen. This is important for some materials. Oxygen can cause oxidation. Oxidation changes the material’s surface. A vacuum stops this. It keeps the material pure during heating.

What about other atmospheres?

You can also use other gases inside. The furnace box is sealed tightly. This lets you control the atmosphere. You might use nitrogen or argon gas. These inert gases don’t react with hot materials. This protects sensitive samples. It gives precise control over the heating environment.

Why ceramic fiber insulation?

The furnace uses ceramic fiber for insulation. This material has great heat resistance. It traps heat inside the chamber very well. This insulation makes the furnace heat up quickly. It also uses less electricity. The outer surface stays cooler. This improves safety in the lab.

Is it safe for lab use?

Yes, designed for laboratory safety. It has protective features. Over-temperature limits prevent dangerous overheating. It includes automatic shut-offs for safety. The exterior stays relatively cool during operation. Always follow basic precautions. Wear heat-resistant gloves. Use a lab coat. Handle hot samples with proper tools.

(Muffle Furnace Oven 1000/1200°C Heat Treatment Vacuum Atmosphere Box Ceramic Fiber Laboratory Heating Equipment)

REQUEST A QUOTE

RELATED PRODUCTS

Vacuum Hot Press Sintering Aluminum Brazing Furnace Aluminum Base Vacuum Brazing Furnace

Atmosphere vacuum argon furnace with Nitrogen Argon and other inert gases

Electric Muffle Oven 1000/1200/1800°C Heat Treatment Vacuum Atmosphere Ceramic Fiber Box Furnace Laboratory Heating Equipment

Automatic Dental Porcelain Furnace High-Performance Vacuum Oven Zirconia Powder Ceramic Vacuum Dental Porcelain Oven Dental Lab

Vacuum burning furnace