Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

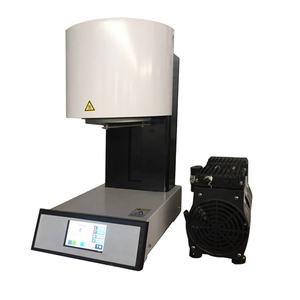

Overview of Dental Furnace

A dental furnace is a specialized piece of equipment used in dental laboratories for processes such as sintering, casting, and baking of dental prosthetics. It ensures precise temperature control and uniform heating, critical for the fabrication of high-quality crowns, bridges, and other dental restorations.

Features of Dental Furnace

Precision Temperature Control: Ensures accurate heating for optimal material properties.

Uniform Heating: Provides even heat distribution to prevent defects in dental restorations.

Programmable Settings: Allows customization of heating cycles for different materials and processes.

High-Temperature Capacity: Capable of reaching temperatures necessary for sintering ceramics and metals.

Compact Design: Space-saving design suitable for laboratory environments.

Safety Features: Includes over-temperature protection and automatic shut-off for safe operation.

(LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used)

Specification of LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used

These dental ceramic honeycomb firing discs with pins are essential tools for dental labs. They are designed for use inside furnaces. They provide a stable platform for firing dental restorations. The honeycomb structure allows heat to circulate evenly. This ensures consistent results during the firing process.

The discs are made from high-grade ceramic material. This LAB material is very durable. It withstands the high temperatures inside dental furnaces. The material resists thermal shock well. This means it doesn’t crack easily when heated or cooled quickly. It maintains its shape over many uses. This gives the disc a long lifespan.

The pins attached to the disc are crucial. They hold the dental restorations securely in place. The pins prevent pieces from shifting or falling during firing. This protects the delicate ceramic work. The pins are also made from robust material. They can handle the furnace heat cycle after cycle. They provide reliable support.

These discs come in standard sizes. They fit most common dental furnaces. The honeycomb pattern offers excellent airflow. Heat reaches all parts of the restoration uniformly. This promotes even sintering and vitrification. It reduces the risk of firing defects. Consistent results are vital for quality dental work.

Using these firing discs improves workflow efficiency. Technicians can trust the stability they provide. The discs support various dental ceramics. They are suitable for crowns, bridges, veneers. The robust LAB material ensures dependable performance. Labs benefit from reduced breakage and consistent outcomes.

(LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used)

Applications of LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used

This disc helps dental labs fire ceramic pieces. Dentists need crowns, bridges, and veneers. These are made from special ceramic powders. Firing makes the powder hard and strong. It uses a dental furnace. The disc holds the pieces during firing.

The disc has a honeycomb pattern. Many small holes cover the surface. This pattern is important. It lets heat move evenly around the ceramic pieces. Uneven heat causes problems. Pieces can crack or warp. The honeycomb design helps prevent this. It supports steady temperature flow.

Pins stick up from the disc surface. Labs use these pins. They place the unfired ceramic pieces onto the pins. The pins hold the pieces securely. This stops pieces from moving or touching each other during firing. Touching can ruin the surface finish. Pins keep everything in place.

This tool saves space inside the furnace. The honeycomb layout fits many pieces close together. Labs fire more items at one time. This makes work faster. Technicians like this efficiency. It saves time and energy.

The material is strong. It handles very high furnace temperatures repeatedly. The disc does not break down easily. It lasts for many firing cycles. This durability saves money. Labs replace discs less often.

Using the disc is straightforward. Technicians place greenware or partially fired items onto the pins. They load the disc into the furnace. They run the firing program. After firing, they remove the disc. They take off the finished pieces. The disc is ready for cleaning and reuse.

The design promotes better results. Even heat distribution means fewer flaws. Consistent color and strength are important. Dental work must look natural and last. This disc supports quality outcomes. It helps labs produce reliable dental ceramics.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used

What is a dental ceramic honeycomb firing disc with pins used for?

This disc holds dental ceramics during firing in a furnace. Pieces like crowns, bridges, and veneers sit on the pins. The disc keeps them steady at high temperatures. This prevents warping and ensures even firing. Proper firing is vital for strong, beautiful dental restorations.

What material is the LAB firing disc made from?

It is made from a special ceramic material. This material withstands extreme furnace heat. It does not break down easily. It also resists chemicals used in dental labs. This material choice ensures reliability and long-term use.

Why does the disc have a honeycomb pattern?

The honeycomb design allows hot air to move freely. Good airflow is critical inside the furnace. It ensures heat reaches every part of the dental piece evenly. This even heating means consistent results. It avoids weak spots or color problems in the finished restoration.

How do I use the firing disc correctly?

Place your unfired dental piece securely on the pins. Position the disc carefully inside the furnace chamber. Follow the specific firing program for your ceramic material. After firing, let everything cool down slowly. Handle the disc gently to avoid cracking.

How long will a firing disc last?

A disc lasts for many firing cycles with proper care. Avoid dropping it or exposing it to sudden temperature shocks. Check it for cracks or damage before each use. Replace it if you see any flaws. A damaged disc can ruin your dental work.

(LAB material of Dental Ceramic Honeycomb Firing Disc Firing Disc with Pins For Furnace Used)

REQUEST A QUOTE

RELATED PRODUCTS

mini smelting furnace melting furnace iron dental lab porcelain furnace

1200C High Temperature Porcelain Lab Dental Zirconia Sintering Furnace Dental ceramics oven

Dental lab zirconia sintering furnace U shape 1800 Mosi2 heating elements factory

PHOENIX 10S Dental Sintering Oven dental Zirconia Sintering furnace For dental Clinic Lab

Dental Porcelain Furnace Press Oven Press Ceramics For Lab Dental Porcelain Press Furnace for Casting Porcelain Bloc