Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

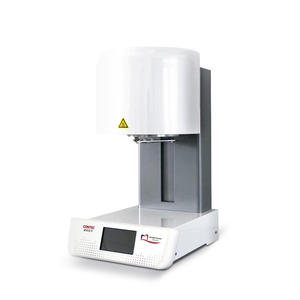

Overview of Dental Furnace

A dental furnace is a specialized piece of equipment used in dental laboratories for processes such as sintering, casting, and baking of dental prosthetics. It ensures precise temperature control and uniform heating, critical for the fabrication of high-quality crowns, bridges, and other dental restorations.

Features of Dental Furnace

Precision Temperature Control: Ensures accurate heating for optimal material properties.

Uniform Heating: Provides even heat distribution to prevent defects in dental restorations.

Programmable Settings: Allows customization of heating cycles for different materials and processes.

High-Temperature Capacity: Capable of reaching temperatures necessary for sintering ceramics and metals.

Compact Design: Space-saving design suitable for laboratory environments.

Safety Features: Includes over-temperature protection and automatic shut-off for safe operation.

(1800c mosi2 heating element heater of dental zirconia denture sintering furnace)

Specification of 1800c mosi2 heating element heater of dental zirconia denture sintering furnace

This burner makes use of molybdenum disilicide, known as MoSi2. It’s constructed for dental sintering heaters. These furnaces bake zirconia dentures. The component operates at 1800 levels Celsius. This high temperature is crucial. Zirconia requires specific warm to come to be solid and look right. MoSi2 elements handle this warm quite possibly. They are dependable for duplicated usage. They warm up fast. They cool off fast also. This helps dental professionals work efficiently. The aspect lasts a long period of time. It withstands oxidation at high temperatures. This indicates less demand for substitutes. It conserves cash over time. The home heating is very steady. The temperature remains constant. This is important forever results. Unequal warmth damages zirconia pieces. MoSi2 components deliver consistent warm. They cover the furnace chamber well. They heat up the zirconia uniformly from all sides. This makes sure strong, accurate dentures whenever. The component connects easily to heating system controls. It works with typical power systems. Installation is uncomplicated for specialists. Upkeep is straightforward. Routine checks keep it working perfectly. It stands up to the demanding cycles of dental labs. Dental professionals depend on dependable sintering. This MoSi2 element provides that dependability. It’s constructed hard for specialist use. It manages everyday sintering easily. It’s the core element for top-notch dental reconstructions. Heater suppliers select it for performance. Labs trust fund it for consistent results.

(1800c mosi2 heating element heater of dental zirconia denture sintering furnace)

Applications of 1800c mosi2 heating element heater of dental zirconia denture sintering furnace

This oral zirconia denture sintering heater uses an unique MoSi2 burner. It heats up to 1800 levels Celsius. Dentists need this high warmth. It makes zirconia dentures strong and long-lasting. Zirconia powder goes into the furnace. The intense warmth modifications it. It ends up being a solid, hard product. This procedure is called sintering. It’s vital for making great dental work.

The furnace makes many sort of dental parts. It makes crowns. It makes bridges. It makes dental implant abutments. All these need to be strong. They require to handle chewing pressures. The heat ensures this toughness. Zirconia dentures have to look all-natural as well. The furnace assists accomplish the right shade and shine. Dentists want natural teeth for individuals.

The MoSi2 heating system is essential. It takes care of the severe warm well. It lasts a long period of time. Dental experts utilize the heating system over and over. The heater remains reliable. It heats the heating system chamber evenly. Every component of the zirconia obtains the very same heat. This makes constant top quality dentures. There are no vulnerable points.

Oral laboratories need reputable tools. This sintering heater provides that. It produces exact, top quality outcomes every single time. Zirconia is a prominent material now. It’s metal-free. Lots of patients prefer it. The heater aids laboratories fulfill this demand. It makes the sintering procedure effective and reliable. Dental experts obtain the strong, stunning reconstructions they require.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 1800c mosi2 heating element heater of dental zirconia denture sintering furnace

MoSi2 heating elements reach 1800°C. This high temperature is vital. Dental zirconia sintering demands extreme heat. The furnace needs consistent, powerful heating. MoSi2 elements deliver this performance. They handle the sintering temperatures perfectly.

Several factors affect element life. High temperatures shorten lifespan. Frequent furnace cycling adds stress. Contamination inside the furnace harms elements. Proper furnace atmosphere matters. Good maintenance extends element life.

Maintaining MoSi2 elements requires care. Avoid physical damage during handling. Keep the furnace chamber clean. Prevent dust buildup on elements. Ensure proper airflow around elements. Follow the furnace operating instructions carefully.

Elements fail for specific reasons. Overheating causes element burnout. Physical damage breaks elements. Contamination degrades element material. Old elements wear out naturally. Poor furnace conditions accelerate failure.

Replace MoSi2 elements periodically. Replace them when performance drops. Replace them after visible damage. Replace them when sintering results weaken. Follow the furnace manufacturer’s replacement schedule. Regular checks help spot failing elements early.

(1800c mosi2 heating element heater of dental zirconia denture sintering furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Dental Porcelain Furnace Press Oven Press Ceramics For Lab Dental Porcelain Press Furnace for Casting Porcelain Bloc

1700C Dental zirconia sintering muffle furnace for

ZTCF-20B Dental Lab Porcelain Furnace Automatic Temperature Adjustment Function 220V

Best ing Authentic s For P P510 DENTAL CERAMIC FURNACES PROGRAMAT With Warranty And Complete Accessories

Dental lab zirconia sintering furnace