Artisan Furnaces - Quality Craftsmanship Tools for Global Artists

PRODUCT PARAMETERS

Description

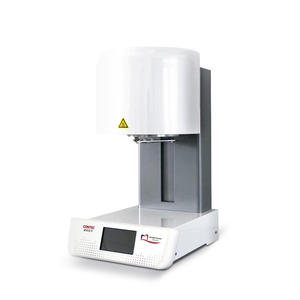

Overview of Dental Furnace

A dental furnace is a specialized piece of equipment used in dental laboratories for processes such as sintering, casting, and baking of dental prosthetics. It ensures precise temperature control and uniform heating, critical for the fabrication of high-quality crowns, bridges, and other dental restorations.

Features of Dental Furnace

Precision Temperature Control: Ensures accurate heating for optimal material properties.

Uniform Heating: Provides even heat distribution to prevent defects in dental restorations.

Programmable Settings: Allows customization of heating cycles for different materials and processes.

High-Temperature Capacity: Capable of reaching temperatures necessary for sintering ceramics and metals.

Compact Design: Space-saving design suitable for laboratory environments.

Safety Features: Includes over-temperature protection and automatic shut-off for safe operation.

(1400C Dental Porcelain Oven for teeth Automatic Dental Veneers Porcelain Furnace Dental Ceramic Oven Porcelain Furnace)

Specification of 1400C Dental Porcelain Oven for teeth Automatic Dental Veneers Porcelain Furnace Dental Ceramic Oven Porcelain Furnace

This oven creates dental crowns, veneers, and bridges. Dentists and lab technicians use it. It fires porcelain and ceramic materials perfectly. The machine heats up to 1400 degrees Celsius. This high temperature is vital. It makes the dental ceramics very strong and natural looking.

The furnace works automatically. You load your dental pieces inside. Then you choose a program. The machine does the rest. It controls the heating and cooling. This ensures consistent results every time. Precision is key for good dental work. This oven delivers that precision.

Safety is important. The furnace has overheat protection. It turns off if things get too hot. The chamber is made from strong stainless steel. This material handles high heat well. Good insulation surrounds the chamber. Ceramic fiber insulation keeps the heat inside efficiently. This saves energy.

The controls are digital. A clear screen shows the temperature and time. Setting programs is straightforward. You see the status easily. The oven interior is spacious. It holds several dental pieces at once. The dimensions are practical for a lab. It fits well on a counter.

The power requirement is standard. It plugs into regular lab outlets. The weight is manageable for placement. This furnace is built to last. It withstands daily lab use. It helps create beautiful, durable dental restorations. Your dental lab needs reliable equipment. This porcelain oven is a solid choice.

(1400C Dental Porcelain Oven for teeth Automatic Dental Veneers Porcelain Furnace Dental Ceramic Oven Porcelain Furnace)

Applications of 1400C Dental Porcelain Oven for teeth Automatic Dental Veneers Porcelain Furnace Dental Ceramic Oven Porcelain Furnace

This dental porcelain oven heats to 1400°C. It’s built for dental labs making ceramic teeth parts. Its main job is firing dental ceramics. This creates strong, natural-looking teeth restorations. Dental veneers are a key application. These thin shells cover the front of teeth. The oven bakes the ceramic material for veneers. It makes them hard and durable. It also gives them a tooth-like appearance. Crowns are another major use. Crowns cover damaged teeth completely. The oven fires the ceramic crowns. This process gives crowns their final shape and strength. Dental bridges also use this oven. Bridges replace one or more missing teeth. They attach to crowns on nearby teeth. The oven fires the ceramic parts for bridges. This joins them securely. Dental inlays and onlays are other applications. These fill cavities or cover tooth cusps. The oven fires these custom ceramic pieces. It ensures a precise fit inside the mouth. The high 1400°C temperature is vital. It fully melts the ceramic particles. This results in dense, strong porcelain. It minimizes pores and weaknesses. The oven provides precise temperature control. Consistent heat is critical for quality. It prevents flaws like cracks or distortions. Even heating avoids uneven shrinkage. This guarantees accurate sizing for restorations. Dental technicians rely on this oven. It fits into their regular lab workflow. They build the ceramic piece first. Then they place it in the oven for firing. After cooling, they finish and polish it. The oven produces realistic tooth colors. It handles the special ceramics dentists choose. These ceramics mimic natural tooth enamel well. This oven is essential for custom dental work. It makes high-quality ceramic teeth parts possible. It helps labs deliver durable, good-looking results.

Company Introduction

Welcome to Designerstudiostore, your premier source for high-quality industrial furnaces designed to meet the stringent demands of modern manufacturing. Our extensive range includes electric, gas, and oil-fired furnaces tailored for various applications such as heat treatment, forging, and laboratory use. With cutting-edge technology and innovative designs, we ensure energy efficiency and superior performance in every product. At Designerstudiostore, we prioritize customer satisfaction by offering customized solutions, reliable after-sales support, and seamless global delivery options. Explore our catalog and discover why businesses worldwide trust us for their heating needs.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 1400C Dental Porcelain Oven for teeth Automatic Dental Veneers Porcelain Furnace Dental Ceramic Oven Porcelain Furnace

What temperature does this dental porcelain oven reach? It heats to 1400 degrees Celsius. This high heat is necessary. It properly melts and sets dental ceramics. It ensures strong veneers and crowns.

Does it work automatically? Yes, it is fully automatic. You program the firing steps beforehand. The oven follows the program exactly. It controls the temperature changes itself. It holds temperatures for set times. It cools down correctly. This automation gives consistent results. It saves technician time.

Is it safe to use? Yes, safety is built in. It has strong insulation. The outside stays cool during operation. It has alarms for problems. These include overheating alerts. There are door safety locks. These features protect the user. They protect the dental lab.

What dental items can it make? It fires many ceramic products. It makes porcelain veneers. It makes crowns. It makes bridges. It makes inlays and onlays. It handles various ceramic materials. These materials need high temperatures. This oven provides that heat.

How do I maintain it? Maintenance is straightforward. Clean the chamber after each use. Check the heating elements regularly. Replace them if needed. Keep the door seal clean and intact. Follow the cleaning schedule. This keeps the oven working well. It prevents firing problems.

(1400C Dental Porcelain Oven for teeth Automatic Dental Veneers Porcelain Furnace Dental Ceramic Oven Porcelain Furnace)

REQUEST A QUOTE

RELATED PRODUCTS

Low Factory , Ready Goods Porcelain Furnace Dental Equipment Dental Ceramic Oven

Intelligent Accurate Temperature Control Dental Porcelain Oven

Zotion dental oven high speed 100 degree per min sintering furnace for zirconia glass ceramics and glazes

Classical porcelain furnace for dental lab high cost-efficient dental lab instrument New century 3-G

1400 degree high temperature Dental Zirconia Fast Sintering Furnace for